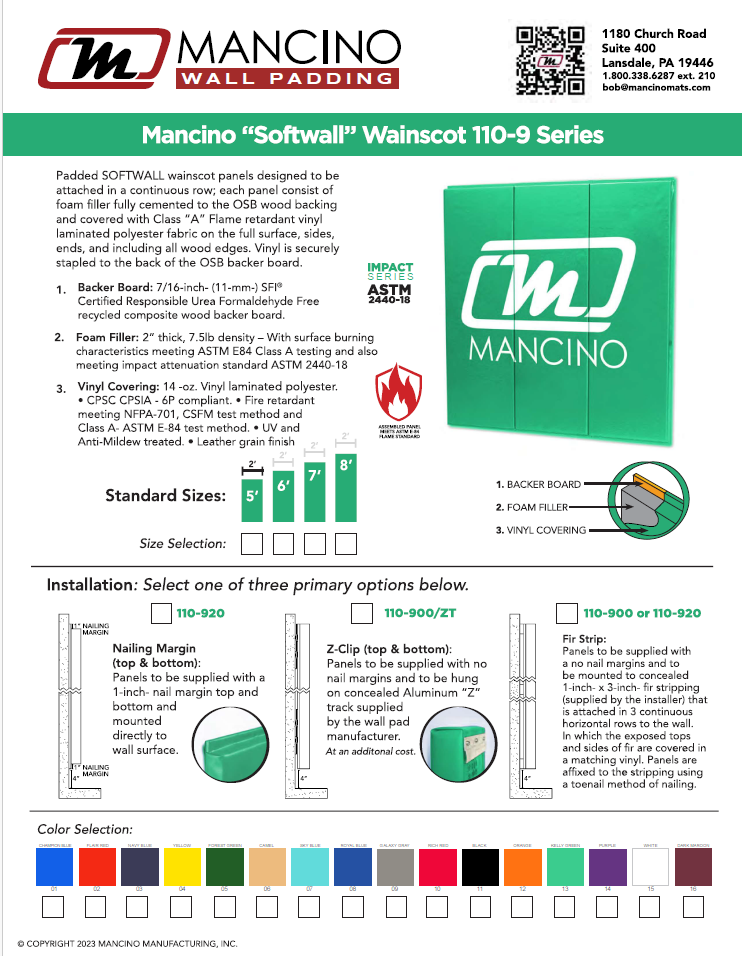

Mancino Softwall Wainscot Class “A” + Impact Rated 900 FIREWALL Series

Description: Padded softwall wainscot panels designed to be attached in a continuous row; each panel consist of foam filler laminated to OSB wood backing and covered with Class “A” Flame retardant vinyl laminated polyester on full surface, sides, ends, and including all wood edges, vinyl is securely stapled to the back of the OSB backer board.

- Backer Board: Not less than 7/16-inch- (11-mm-) SFI® Certified Responsible Urea Formaldehyde Free recycled composite wood backer board. This portion of the product contributes toward satisfying Credit IEQ 4.4 under LEED

- Foam Filler: Not less than 2-inch- (50.8-mm-) thick, Low Smoke Polychloroprene compound foam filler with a density of 9-lb/ ft3. (143-kg/ m3). Achieves Class “A” fire rating under ASTM E-84, with a “smoke developed” index of 450 or less and a “flame spread” index of 25 or less. Also meets the ASTM standard 2440-18 Impact attenuation where the panel has achieved ratings below 1000 HIC and 200 g max.

- Vinyl Covering: 14-oz. Vinyl Laminated Polyester – puncture and tear-resistant. CPSC CPSIA – 6P and lead compliant. Phthalates less than .1% and lead less than 100 ppm. Achieving NFPA-701 CSFM, and a Class “A” fire rating under ASTM E-84, with a “smoke developed” index of 450 or less and a “flame spread” index of 25 or less. UV and BAC Shield (Antibacterial, Antimicrobial, Antifungal, Anti-Mold, and Anti-Mildew) treated.

Sizing: Standard sizes and Custom sizes available.

Customization: All dimensions can be customized to your specifications.

Standard: Available in 4 Standard Sizes

- 24″W x 60″H

- 24″W x 72″H

- 24″W x 84″H

- 24″W x 96″H

Color(s): Vinyl to be selected from manufacturers standard color packet. See Color Chart Tab for color options.

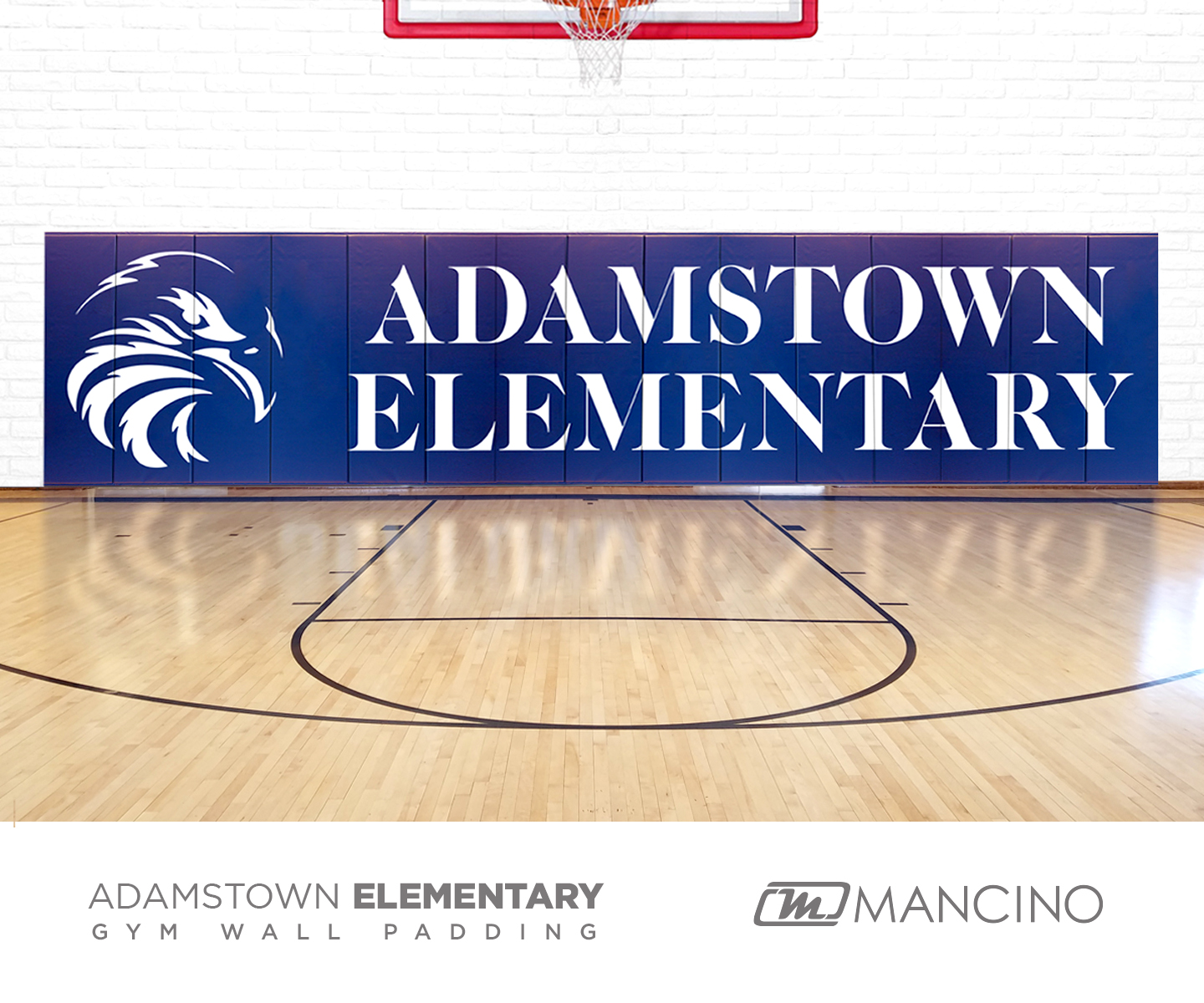

Graphics:

Let our in-house graphics department bring your wall to life with large-scale printing.

At Mancino, your project is our passion.

Composite Testing: Manufacturer must warrant that a composite panel built with similar materials was tested and achieves an overall Class “A” fire rating under ASTM Standard E-84, with a “smoke developed” index of 450 or less and a “flame spread” index of 25 or less. In addition, the manufacturer must also warrant that a composite panel built with similar materials has been tested and passes for ASTM standard 2440-18 Impact attenuation where the panel has achieved ratings below 1000 HIC and 200 g max.

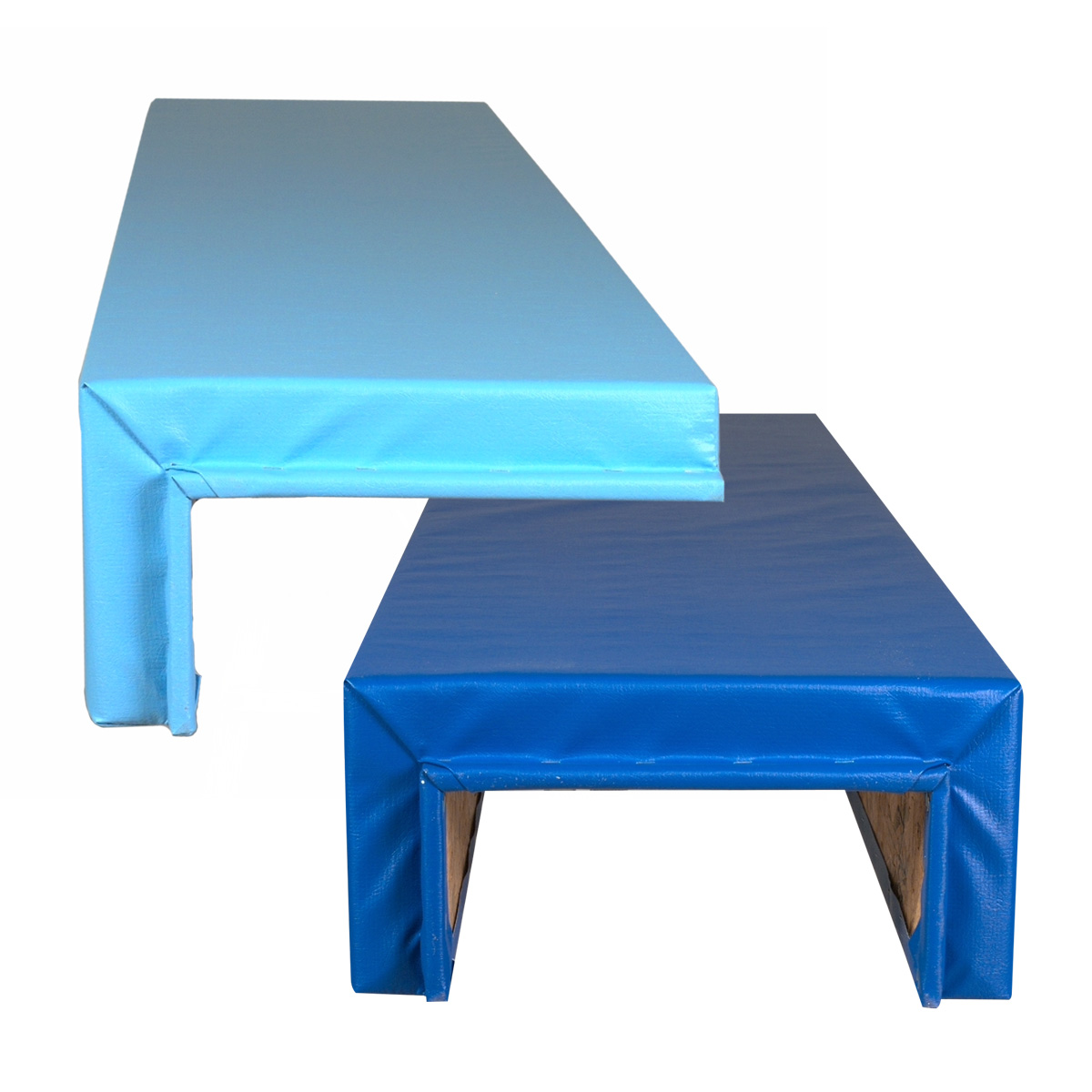

Corner and Column Pads: Prefabricated / Field Fabricated corner and column pads to be built with materials consistent with standard padding specifications as listed above.

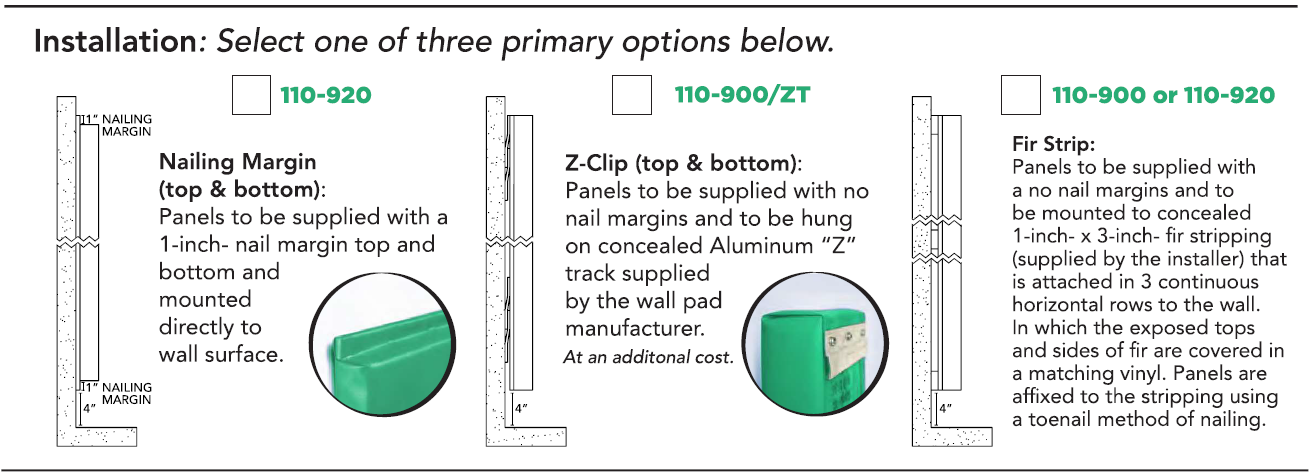

Installation: Mount panels no more than 4” above finished floor as recommended in in ASTM, unless otherwise directed. Install wall padding after painting and electrical have been completed use proper wall anchor hardware.

Selection one of the three primary options listed below:

-

-

-

-

-

-

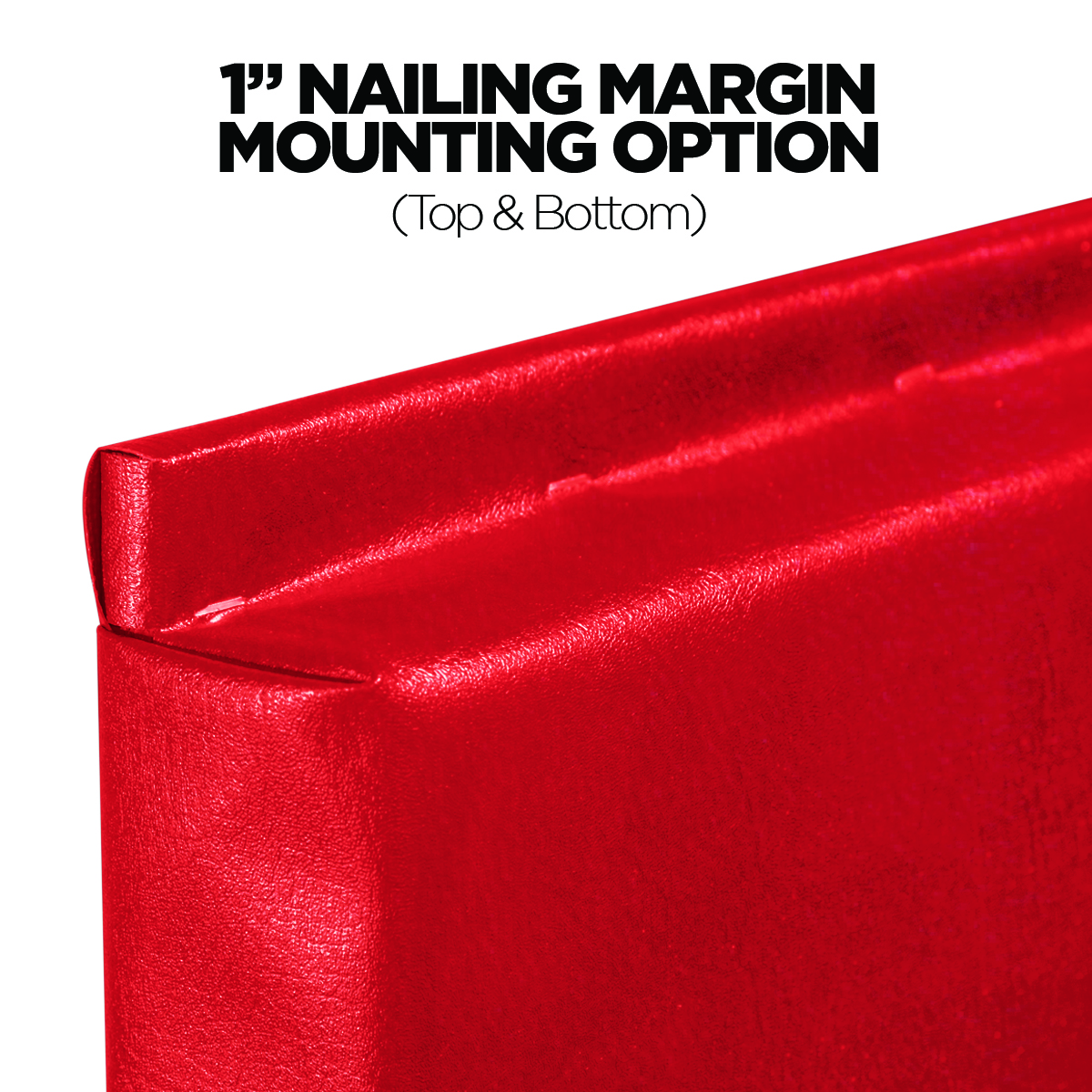

- Option 1 – Panels to be supplied with a 1-inch- nail margin top and bottom and mounted directly to the wall surface.

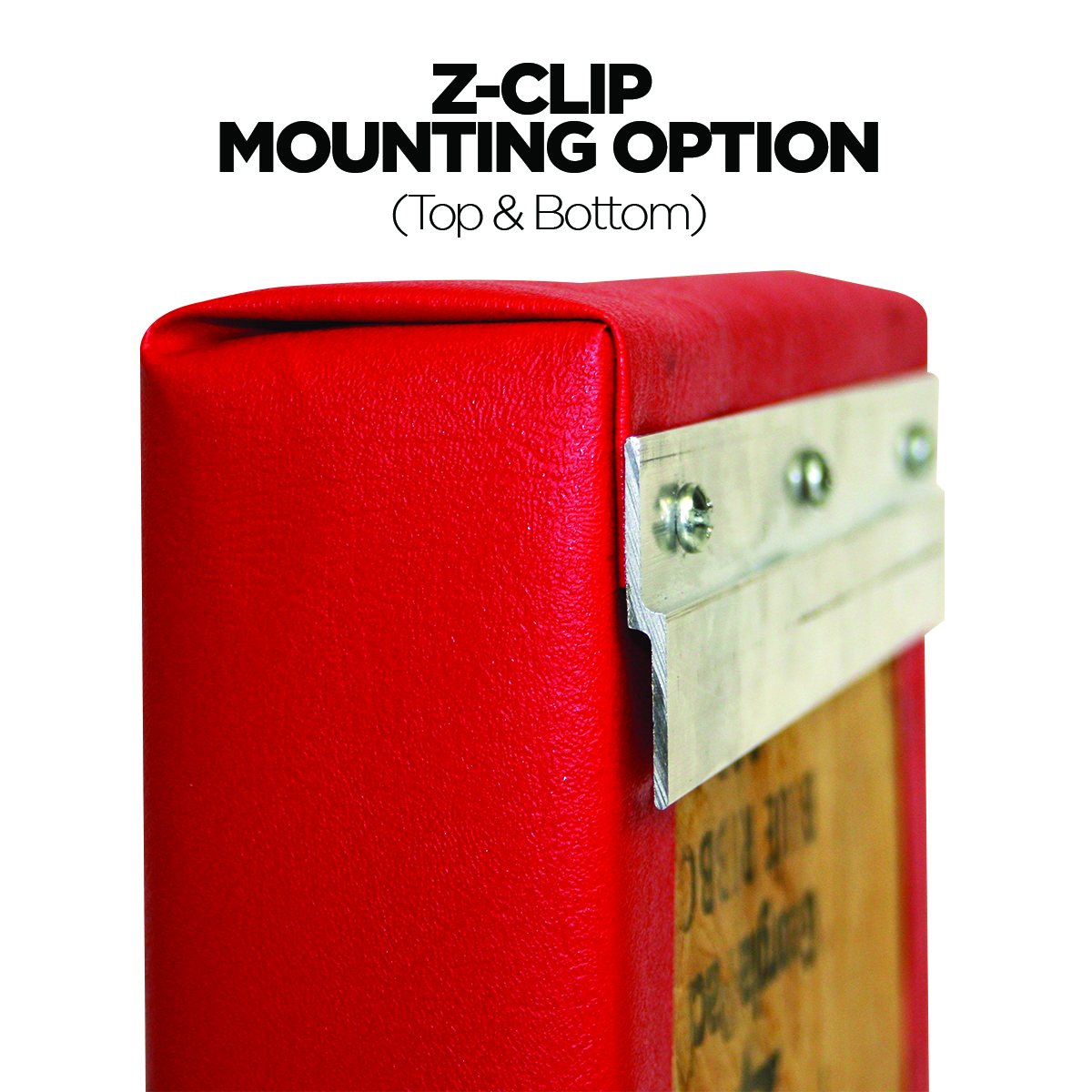

- Option 2 – Panels to be supplied with a no nail margins and to be hung on concealed Aluminum “Z” track supplied by the wall pad manufacturer.

- Option 3 – Panels to be supplied with a no nail margins and to be mounted to concealed 1-inch- x 3-inch- fir stripping that is attached in 3 continuous horizontal rows to the wall. Panels are affixed to the stripping using a toenail method of nailing.

-

-

-

-

-

LEAD TIME: Mancino standard lead time for all non-stock items is 5-6 weeks. In-stock items ship within 3-7 business days. Please call 1-800-338-6287 or email info@mancinomats.com

for the most up-to-date lead time, product availability, special requests or expedited shipping options.